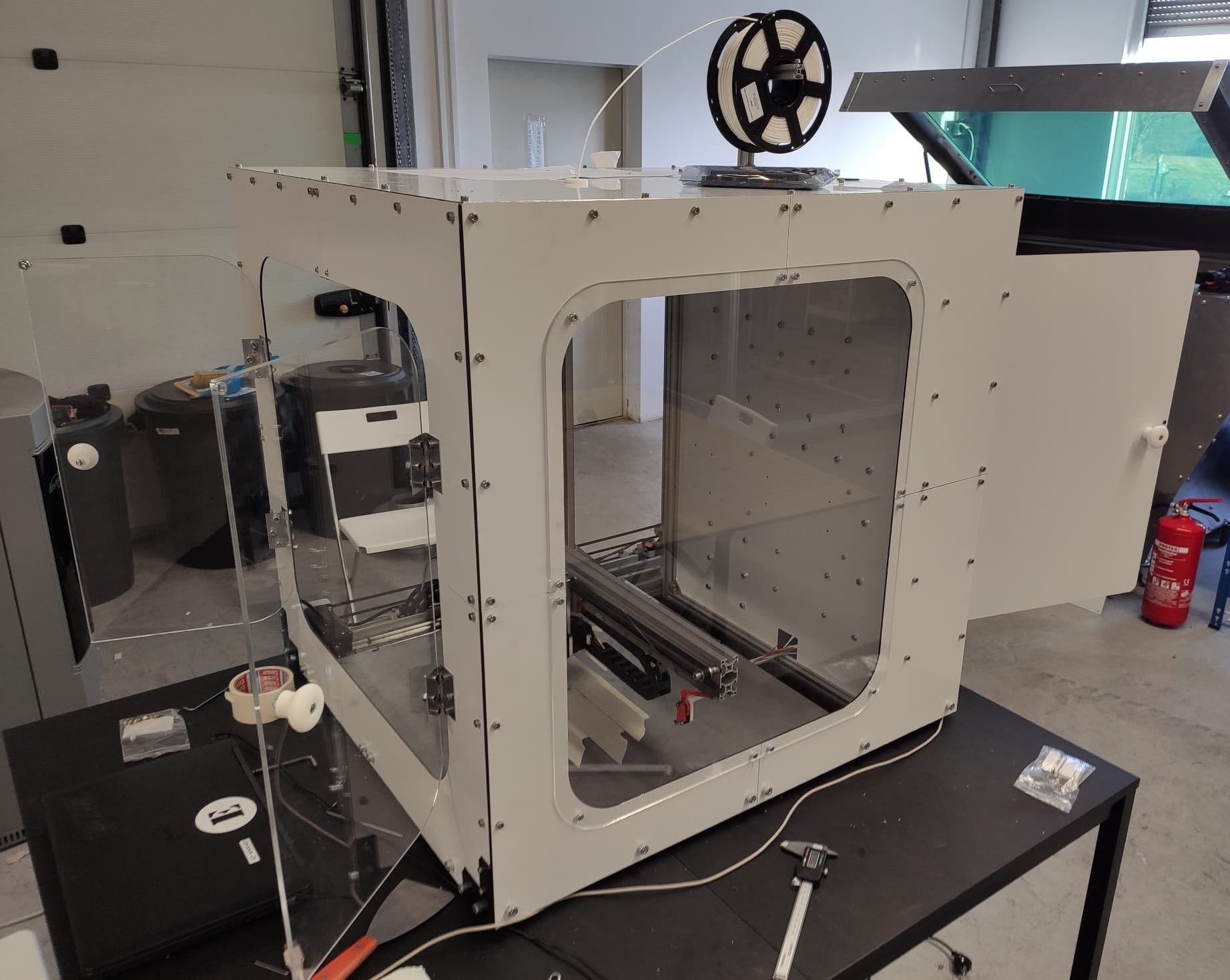

MidFDM

- developed inside Hochschule Rhein-Waal

- 3 axis cantilever system

- 500x500x500mm printing area

- designed for a Fab Lab in Ghana

- fully enclosed

- bed auto-leveling

- BOM ~ 1000$

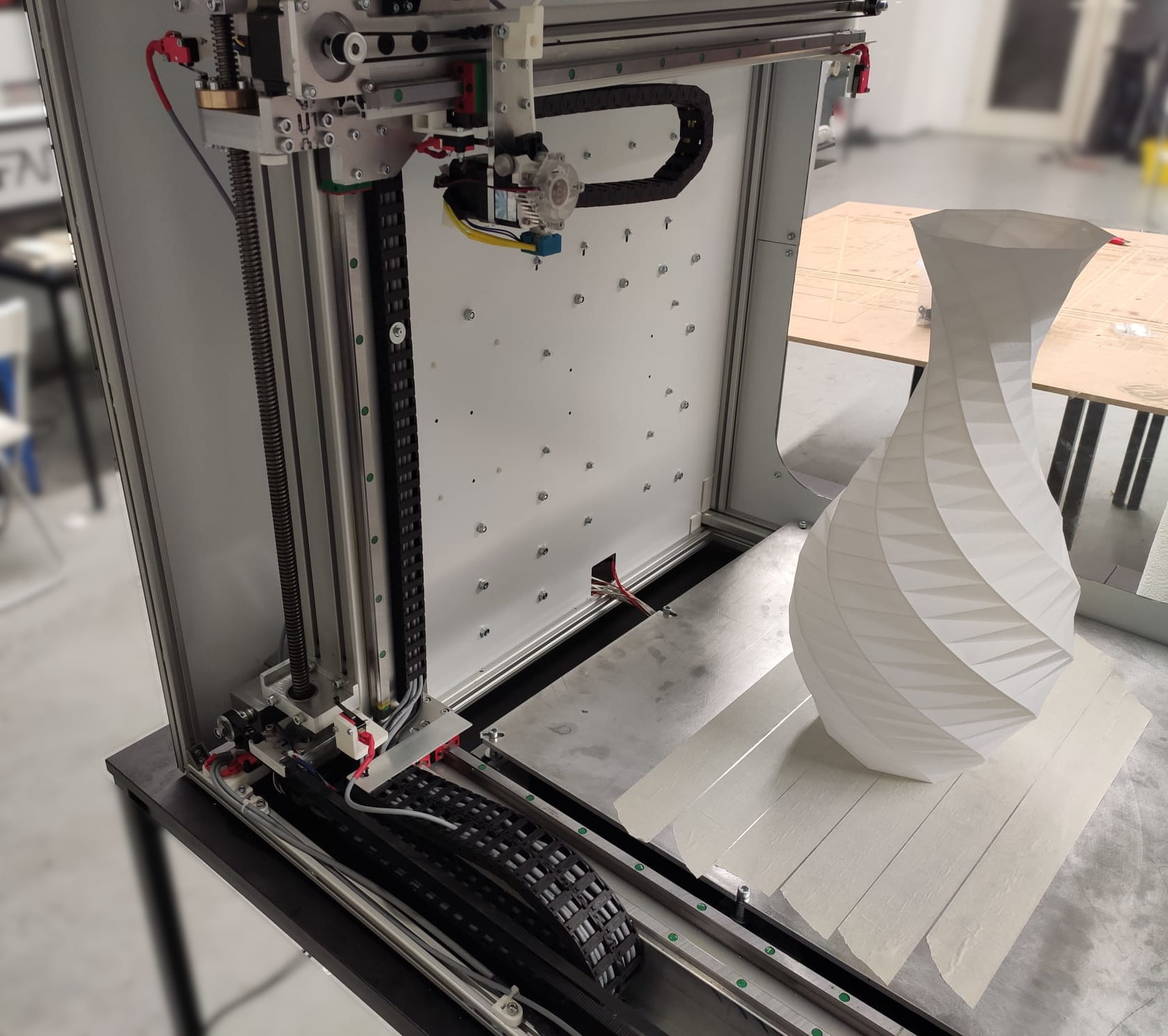

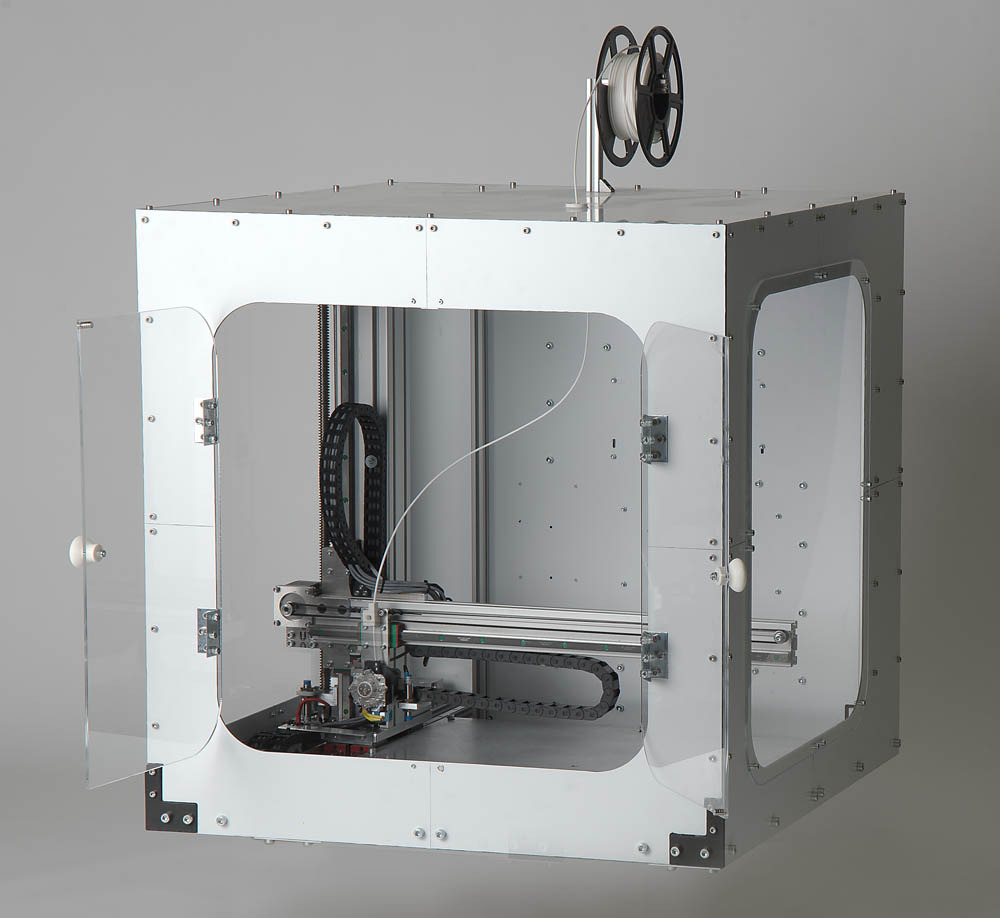

BigFDM ONE

- large scale 3D printer

- 1000x1000x1000mm printing area

- investigation on pellet printing

- evolution of BigFDM

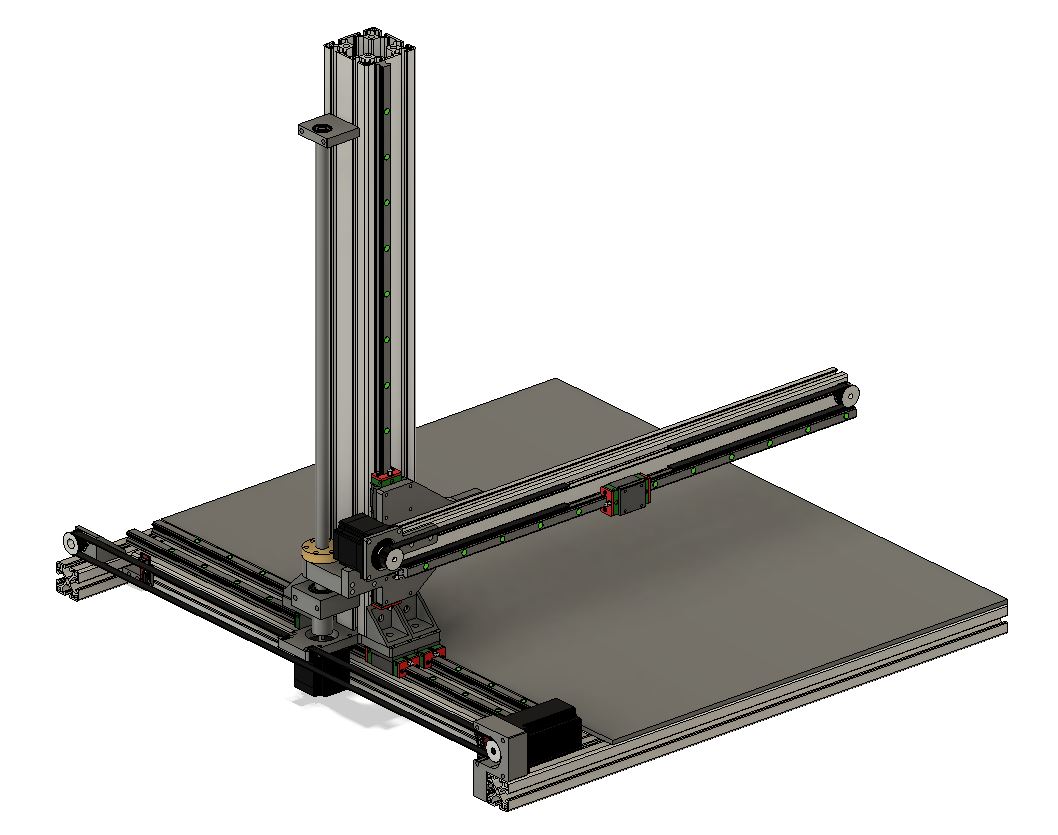

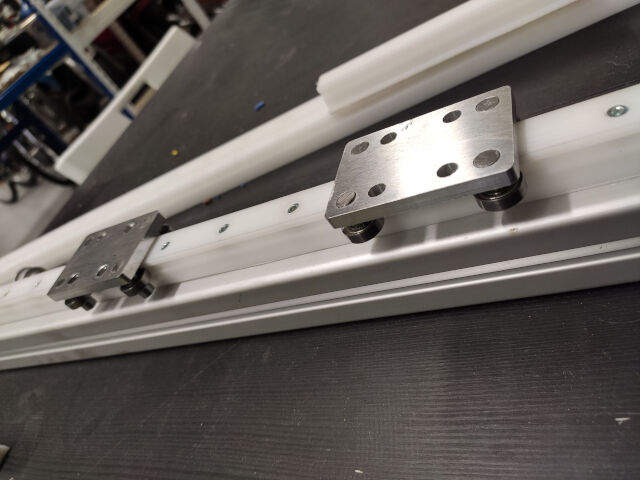

TLinear Guide

- T-shaped linear guide

- made out of POM

- repeatable precise manufacturing

- 9 parts in total + screws

- tested with 30kg load

- tested for 1km usage

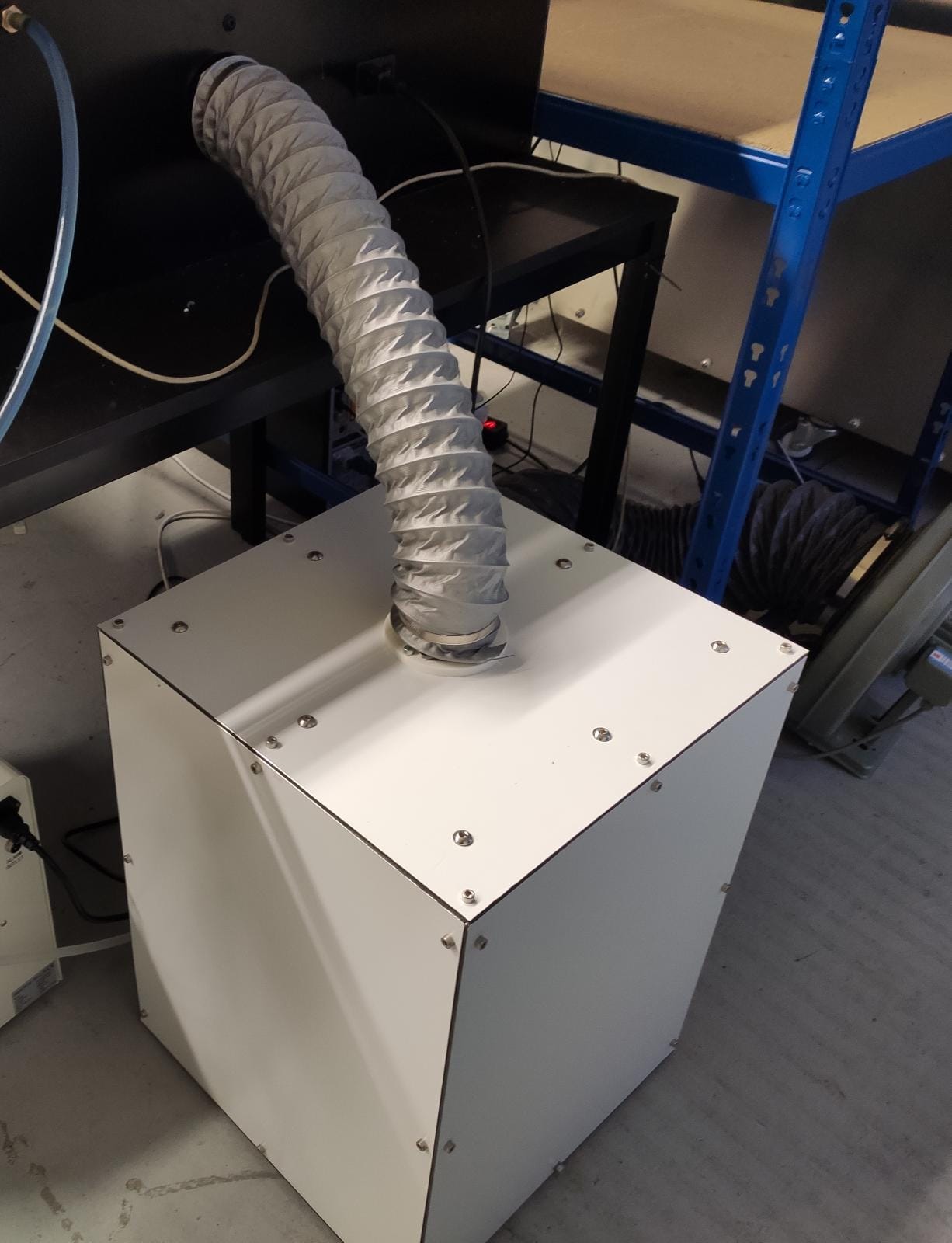

Fabulaser Filter

- self-built laser filtration system

- 4 layers filter design: G3, F8, Hepa H13, and active carbon

- filters are standard sizes

- easy to change the filters

- tested a few hours

Fabulaser V3

- built-in display

- coaxial laser pointer

- auto focus

- auto tuning for the settings

- engraving on non-planar surfaces

- evolution of Fabulaser

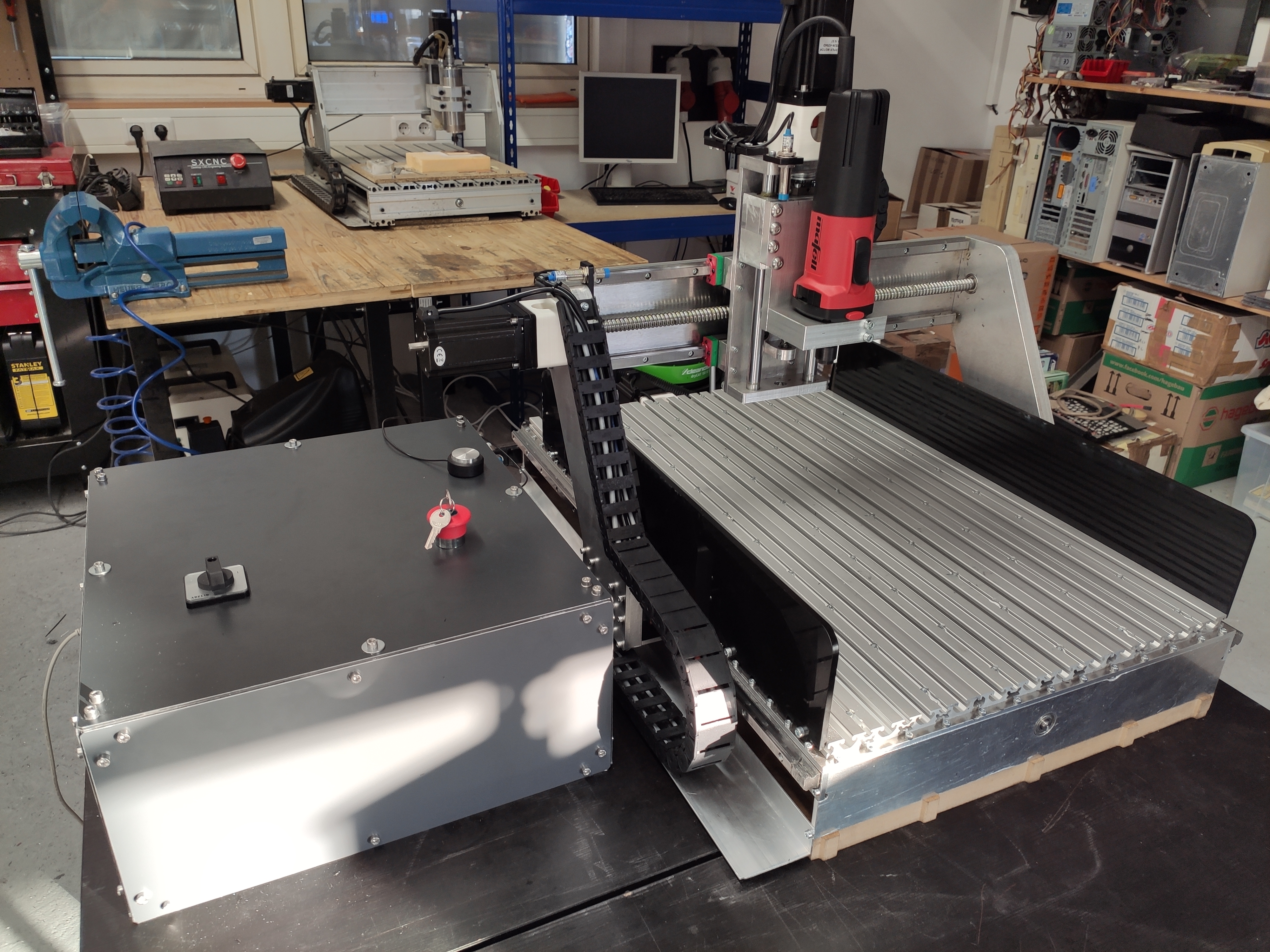

TseNC

- developed inside Hochschule Rhein-Waal

- small portal milling machine

- 600x400x150mm working area

- tool sensor

- inductive endstops

- designed for a Fab Lab in Ghana